Manufacturing the stators for today’s advanced electric vehicle motors can require some tricky steps involving complex technology solutions. One specialist in providing such solutions is bdtronic of Germany which recently used its expanded technology center to work with an EV manufacturer to establish an effective process and machinery approach. The effort at the center helped the company, a process specialist for trickle varnishing of electric motors, recently receive a large order for its powder coating equipment from the unnamed German OEM.

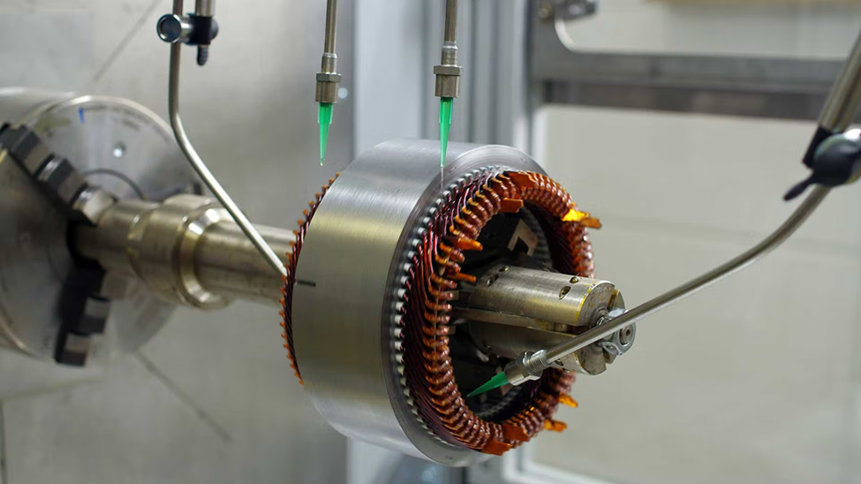

A key challenge in manufacturing modern hairpin stators is that the welded zones of the stator need protection from external conditions in order to achieve electrical insulation. bdtronic offers a modern manufacturing process to cover the coating of the stators’ welded pins with epoxy powder to ensure a safe and reliable product. The technology complements the impregnation of H/EV motors in the powder coating process. This means that impregnation and powder coating can be offered from a single source to ensure process reliability and quality.

The process for hairpin winding calls for rectangular bars of magnet wire to be bent into a hairpin shape. They are then inserted into the slots of the stator in the axial direction. The ends of the hairpin coils are then welded so that the connected coils form a wave shape.

bdtronic has developed a special heating solution that avoids large meter-long ovens to ensure efficient, energy and space saving production. To insulate the welding tips on the stator, the part is preheated and moved into a powder bath. Thanks to the heat of the stator, the epoxy melts on the surfaces and forms a protective layer. With this process, the customers get a uniform covering of the pins and an efficient solution for surface imperfections.

Leading up to the recent order, bdtronic helped convince the OEM by conducting successful trials in its recently enlarged technology center in Weikersheim. The center has 11 rooms covering an area of more than 650 square meters which are equipped with series production equipment. More than 20 specialists from various professional disciplines ranging from chemists with doctorates and engineers to plant mechatronics engineers work at the center. Based on the selected material, component and production requirements, they define the process parameters for series production alongside customers. For more info, see www.bdtronic.com.