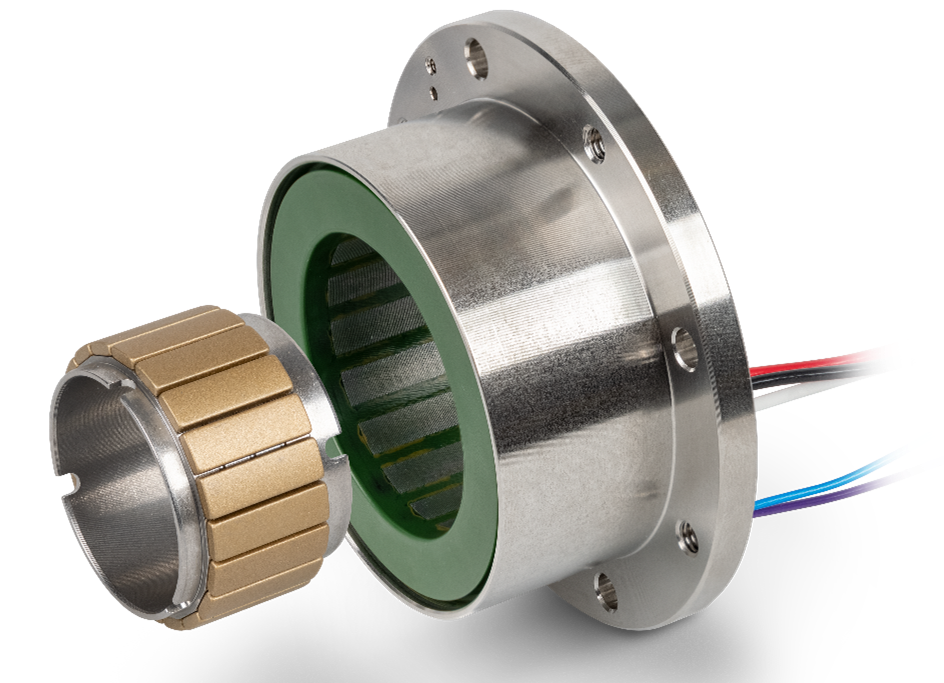

Two new brushless DC motors from maxon of Switzerland feature innovative aspects that enable them to provide important capabilities for design engineers. A frameless brushless-DC motor with new winding technology and a matching encoder really comes into its own in dynamic applications. A new series of flat motors, shown above, also feature special winding technology along with segmented magnets, designed particularly for design engineers grappling with tight spaces.

The ECX flat product family are external-rotor motors that can be configured online and are optimized for maximum performance thanks to the special winding technology, as well as segmented magnets. The ratio of torque to weight and size is second to none and is ideal for use in unmanned aerial vehicle and robotics applications, says maxon.

The iron-wound motors will be available with diameters of 22 mm, 32 mm, and 42 mm, each and in a short or long version. The short versions are just 14 mm, 16 mm or 21 mm in length. The motors are tailored to suit compact drive solutions which need a high torque. All variants will also be available with integrated encoders or with integrated speed controllers as a complete drive system.

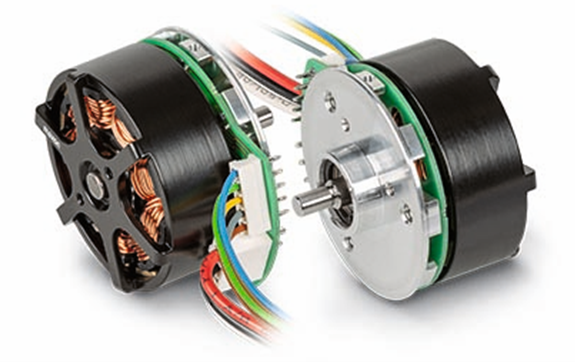

The EC frameless DT50 is the precursor of a new product family developed specifically for dynamic movements and can be easily integrated into a wide range of applications. It really comes into its own in applications where speeds can change in an instant, such as in collaborative robots or exoskeletons, says the company. When installed, it effortlessly reaches a nominal torque of over 500 mNm at a nominal speed of 4,000 rpm. This is despite a stator with an outside diameter of only 50 mm. At the same time, the new winding technology enables a very short motor length with a very large hollow shaft of 28 mm.

The TSX-MAG encoder completes the package. It is a new through-shaft encoder that is not installed directly on the motor axis. The off-axis feature gives engineers more freedom when it comes to design. The encoder can generate both Hall signals and incremental signals, allowing field-oriented commutation of the motor. Plans call for more versions of the TSX-MAG and additional drive combinations to follow soon. For more info see www.maxongroup.com.